This manual mainly tells the related points involved in ANTMINER operation and maintenance. The related personnel shall be familiar with the basic miner maintenance methods, including system upgrade, reset, restore, SD card recovery. Meanwhile, mastering simple fault judgment methods, such as high-temperature protection, fan fault, network fault is essential. Operation and maintenance personnel also need to have a certain understanding of the power, network, environment, etc. of the mining farm and regularly do the corresponding inspection work. Finding problems and resolving them timely can reduce the fault rate of the miner.

Ⅰ. Daily Regular Inspection

II. Notes on Installation

Ⅲ. Miner Troubleshooting Table

Ⅳ. Daily Operation and Maintenance Inspection Table

Ⅰ. Daily Regular Inspection

1. Hashrate Check

1.1 Check the hashrate of the miner every two hours. Batch management software BTC Tools can be used on the site to view or log in to the corresponding mining pool website to check the hashrate status. BTC Tools can set up miners in the mining pool in batches and view the hashrate temperature in real time. It is recommended to install Google Chrome and set it as the default; double-click the scanned miner to enter the background without entering the username and password. If the root password of the miner background has been changed, we need to click the “Setting” in the upper right corner of the BTC Tools software to change to a new password when filling in the username and password in the browser, click here to download BTC Tools software.

1.2 Regularly check the miner’s information to find out whether there are errors or omissions, the remaining 2 spare mining pools need to be filled, excepting for the main mining pool. It is recommended to change the miner’s default root password, and do not download unofficial firmware and upgrade to overclocking firmware to avoid illegal tampering of mining pool miners by malicious firmware. The APMinerTool software can be used to modify the password in batches. The software can also scan and manage the miner, click here to download APMinerTool software。

1.3 When discovering miner with abnormal hashrate, it shall be solved in time, and those cannot be processed on the site shall be removed to repair or return to the factory.

2. Power Check

2.1 A multimeter is used every day to check whether the voltage of the PDU socket of the miner is within the normal value of 220V±10%. If the voltage is too high or too low, the operation will be unstable or it will not work, or it may even burn the power supply or the miner. If the voltage is found abnormal, the electrician should be notified in time.

2.2 Check the three-phase ammeter of the power distribution cabinet every day. If the deviation exceeds 15%, the electrician shall be notified to check whether the three-phase load is balanced. If the three-phase is unbalanced, it may cause the voltage of a certain item to rise, and it is necessary to distribute the miner to the three-phase circuit as evenly as possible. Don’t concentrate on the loop of a certain phase.

2.3 Regularly check whether there is electric leakage in the miner. Some miners’ outer casing may be charged due to poor grounding. When the miner is running, it is easy to damage the control board and the hashboard.

Method 1: When the miner is running, use a multimeter to measure whether there is voltage between the outer casing of the miner and the bare metal of the shelf. If there is voltage, the grounding is not done well (this method requires the outer casing of the miner not to be in contact with the metal of the shelf).

Method 2: When the miner is running, measure whether there is voltage between the metal cover of the miner’s network port and the outer casing of the miner. If there is voltage, the grounding is not done well. (This method requires that the metal cover of the miner’s network port is not in contact with the control panel of the miner). If the grounding is not done well, the electrician needs to deal with it in time.

2.4 Regularly check the plant shelf and the miner socket are grounded (grounding resistance is required to be <4Ω). If they are not grounded or the grounding is not reliable, the professional electrician shall be notified to do the grounding in time. If it is found in the operation and maintenance process that hands touching the miner power supply casing are tingled often, it needs to check whether it is poorly grounded or not grounded

2.5 Regularly check the wire and cable for aging. Use infrared thermometer to check whether the temperature of the circuit breaker, cable, copper bar and connector of the power distribution cabinet is abnormal. If the copper wire or copper nose heats up to 70 degrees Celsius, notify the electrician to handle in time.

2.6 The miner should try to avoid frequent power outages and need to make a plan for power outages. When power is cut off, the power should be turned off from the minimum air switch on the shelf up to the master air switch level by level. When powering on, it should be ensured that the air switch of the shelf connecting to the miner has been completely shut down, and the power is downward level by level by the master air switch, to avoid the impact of the voltage surge and damage to the miner.

3. Network Check

3.1 Regularly check whether the spare broadband line is normal, and check it from the backend of the router or the laptop spare cable. The networks for mining and life need to be separated to avoid visits to unidentified websites in the living area that involve network security, and also prevent downloading and watching video that occupies the network speed affecting the fluctuation of hashrate due to the connection between the miner and the mining pool. In special circumstances where it needs to share the factory network, the network manager needs to limit the speed of IP in the living area on the router or switch side, and prevent access to unknown websites.

3.2 Use the “Ping” command to test whether the delay of the mining pool used by the current miner is stable. If the delay exceeds 100ms, the internal and external networks need to be checked. The local network is checked by the network manager for network equipment failure. The external network needs to be checked by the broadband operator for the equipment line. If the delay is too high, it will cause the hashrate to fluctuate. The Ping function option is located in Network-Diagnostics. When the network is checked with a miner which is 0 hashrate, if Ping is not impassable to the currently used mining pool address, it is a network failure.

3.3 Check the temperature of the network equipment every day. If the equipment shell reaches 45 degrees Celsius or more, it needs to change the position or install a fan to dissipate heat. Do not place the network equipment and network cable at the miner outlet of warm air. If the CPU temperature of the network equipment is too high, it will affect stability and even crash. It is recommended to use high-quality network cable as the main network cable. When the network is disconnected for more than 15 minutes, the miner should be powered off. The power consumption and hashrate of the miner are corresponding. If the hashrate is insufficient or 0, the power consumption will be reduced accordingly.

4. Temperature and Humidity Check

4.1 High Temperature Check

Measure the temperature at the air inlet of the miner every day, and try to control it at 10 to 25 degrees Celsius. If the temperature near the air inlet of the miner exceeds 30 degrees Celsius, it will easily cause high-temperature protection and 0 hashrate, and the temperature needs to be lowered in time. It is possible to check whether there is warm air backflow at the position of the miner, and it needs to pay attention to the fact that the small fan of some third-party power supply and the fan of the miner are opposite to each other, causing temperature superposition; at that time, the power supply direction needs to be repositioned. If the hardware of the miner with high-temperature protection and 0 hashrate is not damaged, the hashrate can be restored after lowering the ambient temperature and turning on the miner. The mining farm needs to formulate a plan to lower the ambient temperature as soon as possible, such as installing a water curtain, installing a negative pressure fan, and making hot and cold isolation (materials such as plates are used to block the warm air from flowing back to the cold air area of the air inlet).

4.2 Low-Temperature Check

It is required that the operating environment temperature for the ANTMINER is 0-40 degrees Celsius. While in some regions, the temperature in winter can be very low, reaching minus 10-20 degrees Celsius, which may cause some issues for ANTMINER series like 17e & 17+, such as burnt hashboard, missing hashboard, missing chips, low-temperature protection, high-temperature protection, and failing to read temperature sensor. click Operating Your Miner under Low -Temperature Environment to check the details.

4.3 Humidity Check

Measure the humidity near the air inlet of the miner every day, check whether there is condensation at the position of the shelf, miner, power line, etc. If the humidity exceeds 65%RH, it needs to be reduced. If the distance between the water curtain and the shelf is too close, the humidity will increase. Generally, the distance should be 2-3 meters, not too close or too far (if the distance is too far, it will weaken the cooling effect). If the long-term humidity is large, and there is large-scale chemical plant nearby that causes poor air quality, it will accelerate the corrosion or even cause the hashboard to scrap. The water curtain’s water flow can be reduced as needed to reduce the inlet air humidity. It is recommended that the miner should not run near saline-alkali land or near the sea, which will easily lead to the oxidation and corrosion of the miner.

4.4 Water Curtain Check

Check the water curtain every day for abnormal water leakage to the ground inside the plant, whether the water flows evenly, whether there is any white alkali residue; water curtain blockage or uneven distribution of water flow will reduce the effect and affect the temperature, so the water curtain should be cleaned regularly. It is also necessary to regularly check whether the water volume in the water curtain is normal and whether the pump is abnormal.

Right: If there are many dust worms and other catkins around the water curtain, add a layer of gauze to block the water curtain.

5. Environmental Check

5.1 Check the operation of the plant’s negative pressure fan every day to see if there is a slow speed or suspension. The mining farm needs to be cleaned in place to make the ground dust-free.

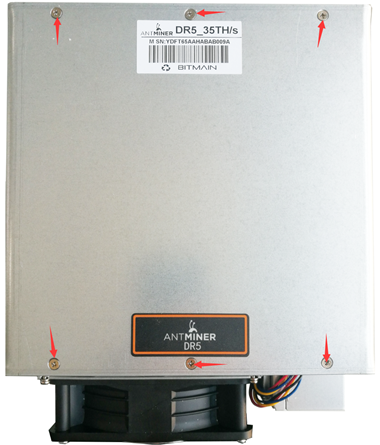

5.2 Regularly check the dust of the miner every month. You can unpack the front fan of the miner to view. If a large amount of dust, catkins, etc. are found in the heat sinks position, which block the air flue and cause high-temperature protection, it needs to be cleaned up in time. Gently brush off the dust with an antistatic soft brush. Be careful not to use too hard brushes or use too much force. Otherwise, the heat sinks may fall off and the dust may be blown off by the fan after processing with brush. (Note only to remove the 4 screws on the fan when removing the fan, do not remove the screw with the tamper-proof label on the body)

5.3 Northern mining farms are generally dusty. Check the dust screen every week and regularly clean the filters with tools such as vacuum cleaners. If there is a lot of dust and sand in the factory, but the filters protection is not installed, it is necessary to take appropriate dust prevention measures in time.

5.4 On rainy days, note to prevent rain or water in the plant from affecting the miner, especially positions at the door and some unclosed areas.

6. Visual Check

6.1 Check whether the air inlet of the miner is blocked by any garbage or paper scrap every day, and clean it up in time to avoid affecting the air volume and causing high- temperature protection and 0 hashrate.

6.2 Check whether the indicator light of the miner is normal every day, and the red light indicates abnormality that shall be processed. Check whether the two fans of the miner are running. If the fan blades are found to be damaged or not running, they shall be replaced in time; you can also check whether the fan is faulty from the backstage Kernel log. When replacing the fan, be careful not to install it reversely, otherwise, the air will not be discharged from the miner.

6.3 Check whether the network cable is damaged and cannot be used, and whether the power cable is abnormally overheated. It is not recommended to use 1/2 power cables, which are easily overloaded. It is recommended to purchase power cables of 10A or above at 220V, and the length is within 1.5m.

II. Notes on Installation and Disassembly of the Miner

1. Notes on Installation

1.1 Check the appearance of the miner for signs of violent bumping, and shake the miner to check whether there is a heat sink falling out. Check whether the appearance of the two fans is damaged or not. For new all-in-one machines, check the bare part of the copper bar for tilting, which will cause the board fall and other faults, and it needs to be restored in place.

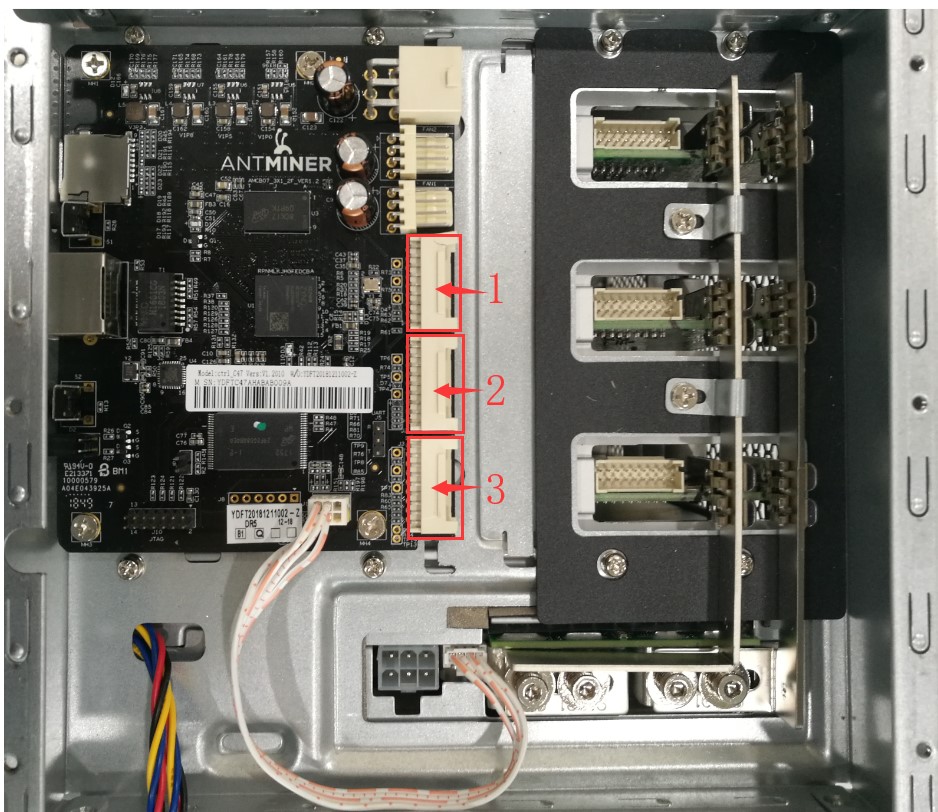

1.2 Before putting the miners on the shelf, check whether the cables (fan, power supply 6pin, and hashboard) are plugged in place without loosening. The direction of the 6Pin line of the power board must not be reversed. The 6Pin power cable can’t be missed to be plugged into the control board, which will cause the hashboard to burn out. Inserting the power supply line of the control board reversely will also cause the control board to burn. Loosening and reverse inserting may cause the machine to burn. Loosening or poor contact between the power line and the socket is not allowed. Please pay attention when purchasing the socket and power line.

1.3 Handle miners gently. It is forbidden to directly carry the hashboard cable or power line with hands, and it is forbidden to throw it away from the height. When workers are handling the miner, they must be told not to throw about, which will cause the heat sinks and chips on the hashboard inside the miner to fall or impact the external fan, and cause damage or even scrapping.

1.4 After the new miners are put on the shelf, modify the mining pool server address and the server with the batch software APMinerTool or BTC Tools, set the fixed IP according to the requirements, and confirm whether the miner’s hashrate is normal. When a single miner is put on the shelf, it is set to the original shelf position IP.

1.5 Pay attention to planning the IP address when deploying the miners in batches, to facilitate fixing the IP address subsequently, dividing the DHCP and staggering the fixed static IP. If there are 100 miners on the shelf, the gateway can be set to 172.16.1.254, DHCP can be set to 172.16.1.101-240, and the reserved IP (1-100) can be used for subsequent fixed IP. Generally, one shelf is managed by one network segment, and the APMinerTool tool “Configure IP” option can be used for the IP address of the fixed miner, click here to check the tutorial.

2. Notes on Disassembly of the Miner

2.1 Before taking the miner out the shelf, confirm whether the miner fault can be restored to normal at the site. Generally, problems such as high-temperature protection, fan failure, network failure, and system failure (stocking with some spare parts is suggested in mining farms) can be solved on the site. Minimize misjudgment of fault and returning of normal machines after sale. Misjudgment of fan fault can be viewed by pulling down the log Kernel log to the bottom at the miner background. For the fan log of S9, T9+ series, FAN 2 corresponds to Fan 5.

2.2 Confirm whether the IP corresponds to the real object to avoid taking the wrong miner. If the miner IP cannot be confirmed, IP searching software IP Reporter can be used, directly click Start and then press the IP key of the miner or click the “Configure IP” option on the APMinerTool software and confirm by pressing the IP button of the miner.

2.3 Before putting the miners on the shelves and taking them out the shelves, it is necessary to power off and then operate. Handle gently, it is forbidden to carry the hashboard cable or power cable by hands, or throwing from the height.

2.4 If the factory shelf has cold heat isolation, the vacancy after the miner is removed should be blocked to avoid warm air return. The miners off the shelf should be dust-proof and moisture-proof, placed smoothly and neatly in the designated area, waiting for on-site maintenance or returning to the factory for after-sale service.

Ⅲ. Miner Troubleshooting Table

There are various reasons for the failure of the miner. First, check the network, upgrade the firmware, reset, check the cable, replace the power supply, reflash the control panel, clean the dust, and lower the ambient temperature, etc. If it is still not solved, it is necessary to check the power and environment. If it can’t be solved on site, it shall return to after-sales service, which can be summarized as follows:

| Troubleshooting Table V1.0 for Common Miner Faults | |||

| No. | Miner Faults | Troubleshooting Method | |

| 1 | The miner is not powered | 1.Check whether the power supply and power cables are plugged in and powered 2.Measure with a multimeter for whether the power supply 6pin line has 12V output 3.Check the control board and the hashboard for burnout marks |

1. Re-plug the line 2. Replace the faulty power supply 3. Replace the control board |

| 2 | Cannot scan the miner | 1.Restore to factory settings or power off, press IP report button to reset 2.Check whether the miner and computer are in the same network 3.The router does not turn on DHCP or the renewal time is too long 4.Add a wrong IP segment |

1. Re-find IP 2. Connect the miner and computer to the same network 3. The router turns on DHCP and sets renewal to 2 hours 4. Re-add the correct IP segment |

| 3 | Cannot visit or enter the backstage of the miner | 1.The original IP is inconsistent with the current network after the miner is relocated 2. Browser compatibility issues 3. Check if the password is correct 4. Restore to factory settings or brush the control board with card |

1. Change the current network to be consistent with the previous site 2. Use Google Chrome or Firefox |

| 4 | No data on the backstage or 0 hashrate | 1. Check if the fan cable is plugged in or the fan is faulty 2. Check if the miner can ping the mining pool 3. Check if the fixed IP setting of the miner is wrong 4. Check if the mining pool server address and the server of the miner is set correctly |

1. Replace the fan or re-plug the fan cable 2. Network troubleshooting or replace the mining pool 3. Reset and set the fixed IP again 4. Reset the mining pool server address and the server |

| 5 | The miner has insufficient board hashrate | 1. Check if the miner 6Pin power line and cable are plugged in firmly 2. Check if the PSU is faulty |

1. Re-plug the line 2. Replace the faulty power supply |

| 6 | Miner’s red light flashes | 1. Check if the network is normal 2. Check if the machine is in high temperature protection |

1. Check if the fan is faulty 2. Lower the ambient temperature and clean the dust |

| 7 | Run for a period of time with fewer chips or partial chips. Enter X to restart normally | 1. Check the power supply 2. Check grounding 3. Check the network |

1. Replace the power supply 2. Conduct grounding 3. Replace the network device or change the main network |

| 8 | Run for a period of time with whole hashboard chip X to restart normally | 1. Check the power supply 2. check grounding 3. Check the ambient temperature and the dust of the miner |

1. Replace the power supply 2. Conduct grounding 3. Lower the ambient temperature, the miner cleans the dust |

| 9 | Batch software scans a small number of miners | 1. Not add all network segments 2. Check the internal network fault, whether the switch is powered off |

1. Re-add network segment 2. LAN troubleshooting and check the switch |

| 10 | The miner runs for a period of time with 0 hashrate, restart to restore hashrate | 1. Check if the power supply is abnormal 2. Check if the temperature is abnormal |

1. Replace the power supply 2. Lower the ambient temperature, the miner cleans the dust |

| 11 | SD card recovery system failed | 1. Whether the card recovery image is wrong 2. Memory card compatibility issues 3. Whether the SD card slot looses |

1. Copy the file again after formatting 2. Replace the memory card 3. Clean the card slot and press the card slot to fully contact |

Ⅳ. Daily Operation and Maintenance Inspection Table

The items that need to be inspected in daily operation and maintenance of the mining farm should be recorded and improved accordingly to reduce the failure rate.

| Daily Operation and Maintenance Inspection Table of the Mining Farm V1.0 | ||||||

| Inspection object | Inspection content | Reference value | Inspection result | Remark | Inspection date | Inspector |

|

Hashrate situation

|

Batch tool scans low hashrate | (unit) | ||||

| Whether the mining pool miner is missing or wrong | (unit) | |||||

| Number of miners in high temperature protection | (unit) | |||||

|

Power situation

|

Measure whether the socket voltage value is normal | 220V±10% | ||||

| Whether the shelves and power outlets are grounded |

Resistance <4Ω

|

|||||

| Whether the value of the three-phase ammeter is balanced |

Deviation within 15%

|

|||||

| Detect if there is leakage in the miner | Voltage <1V | |||||

|

Network situation

|

Ping current mine delay | Below 100ms | ||||

| Network equipment casing temperature | Below 45℃ | |||||

|

If the switch is powered off

|

||||||

|

If the standby broadband line is normal

|

||||||

|

Temperature and humidity

|

Air inlet temperature | Below 30℃ | ||||

| Air inlet humidity | Below 65%RH | |||||

|

If the negative pressure fan runs normally

|

||||||

|

Whether the shelf has warm air return

|

||||||

|

If the water flow of the water curtain and reservoir is normal

|

||||||

|

If the water curtain leaks or the alkali is not smooth

|

||||||

|

Environmental situation

|

Miner dust situation

|

|||||

|

Factory catkin situation

|

||||||

|

Factory floor and shelf dust situation

|

||||||

|

Miner appearance

|

If there is foreign matter blocking at the inlet and outlet of the miner

|

|||||

|

If the miner fan does not turn or the fan blade is damaged

|

||||||

|

If the miner tuyere and the hot and cold isolation port correspond

|

||||||